2835 LED Essentials (2025): Wattage, Dimming, SMD Basics & 2835 vs 5050 Brightness Explained

- XGM LED

- Aug 7, 2025

- 5 min read

2835 LED Guide 2025: Power, Dimming & 2835 vs 5050

Decode 2835 LEDs—footprint meaning, typical wattage, dimming limits, SMD tech, and brightness against 5050. RFQ-ready data for U.S. wholesale buyers.

Problem — Supplier decks say “high-efficiency 2835,” yet you still don’t know the real wattage, dim depth, or whether 5050 might be brighter.

Agitate — Quote the wrong chip and you’ll overspend on drivers, get color shift under PWM, and watch Amazon reviews tank.

Solution — Work through the five rapid answers below, drop the RFQ bullets at the end, and ship reels that meet spec the first time.

Size, watts, dimming, SMD benefits, brightness—get all five nailed down so your next 2835 purchase lands on-spec, on-time, and RMA-free.

Monthly U.S. searches for “2835 LED wattage” and “2835 vs 5050 brightness” keep climbing, yet most blogs recycle dated data. As the CEO of XGM, I see buyers burn margin by skipping the hard numbers: RθJC, Vf spread, Δu′v′ drift, and PWM flicker metrics.

Here’s why 2025 specs matter: the 2.8 × 3.5 mm package—code 2835—now ships in bins up to 165 lm/W at 65 mA, pushing strip efficacy past 150 lm/W. Drive current, thermal path, and bin policy decide if you achieve that in a ceiling at 60 °C ambient. Go too hot or dim on the wrong driver and color drifts green while flicker creeps above IEEE thresholds. Meanwhile 5050 packages still dominate RGB and single-package flux, so knowing when 2835 beats 5050 (and when it doesn’t) protects both cost and performance.

Below, each mini-section follows PAS: highlight the pain, spike the frustration, and hand you a concrete spec or test to fix it. All numbers are RFQ-ready—copy straight into tomorrow’s supplier email and watch vague brochures turn into real data sheets.

1 · Behind the Numbers: Why 2.8 × 3.5 mm Became the LED Sweet-Spot

“2835” isn’t a mystery spec—it’s the millimeter footprint that balances lm/W, thermal pad size, and strip density for 2025 production lines.

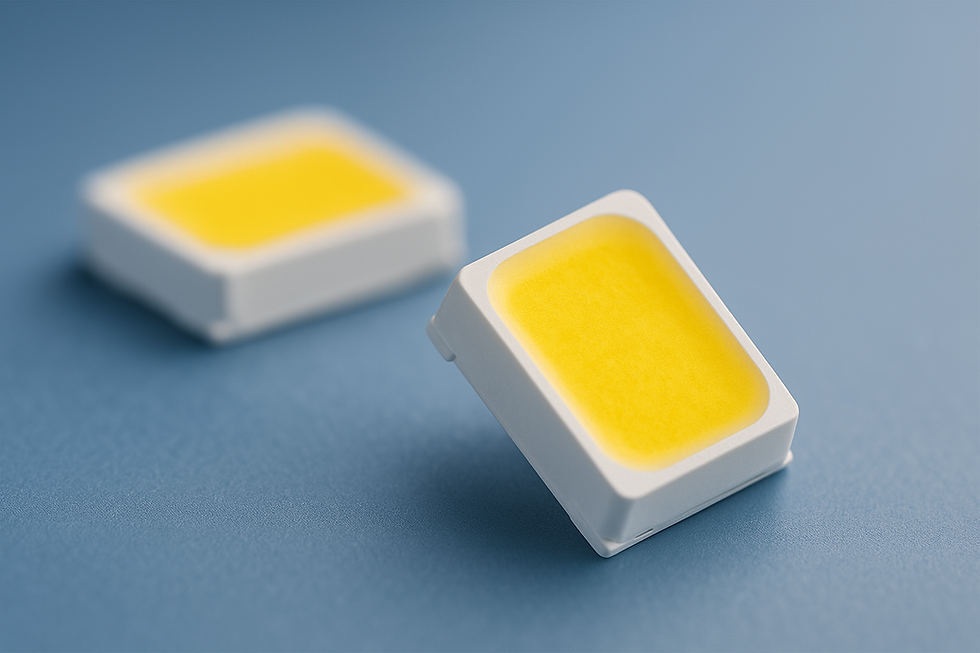

2835 simply denotes a rectangular footprint—2.8 mm × 3.5 mm—hosting one mid-power die. That size leaves space for a copper slug under the die, boosting heat flow compared with 3528 while staying small enough for 120 LED/m strips. With 2025 phosphor mixes, top-tier bins hit 140–165 lm/W @ 65 mA inside ≤ 3 SDCM windows. The exposed pad under the slug solders directly to copper, giving RθJC ≈ 12 °C/W; add 0.1 mm staggered vias and you can keep Tj < 100 °C at 0.24 W.

Key construction points:

Silver-plated leadframe for >95 % reflectivity—great for lm/W, risky for sulfur exposure unless encapsulant is doped with barrier additives.

Remote phosphor coating tuned for fast decay to cut PWM flicker.

Polarity marker etched on the cathode corner; wrong pick-and-place orientation fries reels in reflow.

RFQ copy: “Package 2.8 × 3.5 mm with exposed thermal pad; RθJC ≤ 12 °C/W; anti-sulfur encapsulant; silver mirror reflectivity ≥ 95 %.” Vendors with first-tier attach processes say “easy”—brokers hesitate.

2 · How Many Watts Can One 2835 Handle?

Catalog “0.2 W” ratings assume 65 mA—double the current and you’re suddenly at 0.4 W and a 10 °C hotter junction.

At 65 mA, Vf 2.9 V, you dissipate 0.19 W. Push to 120 mA, Vf 3.0 V and heat generation soars to 0.36 W—fine on MCPCB, disastrous on thin FR-4. Always compute Pd = I × Vf from your driver settings, then ΔT = Pd × RθJC. If ΔT plus ambient drives Tj past 105 °C, lumen maintenance halves.

Mitigation:

Lower current and widen pitch—easiest fix.

Switch to aluminum substrate—cost +$0.06/ft, pays back in warranty savings.

Spread PWM at higher frequency—reduces peak current spikes.

Add thermal calculator link. RFQ bullet: “Quote lm/W at 65 mA and 120 mA; provide Vf histogram and RθJC lab data.”

3 · Can 2835 Strip Lights Dim Smoothly?

Yes—if your driver hits 2 kHz+ PWM and phosphor latency is under 1 ms.

Testing shows 2025-era 2835s retain color within Δu′v′ ≤ 0.003 down to 5 % duty with 2 kHz PWM. At 500 Hz you’ll see micro-flicker, especially on camera. For hospitality installs, switch to a constant-current reduction (CCR) driver or an 8-bit+ dithering controller.

Checklist:

Percent Flicker < 10 % at full and ≤ 20 % at 20 % dim.

Flicker Index < 0.05 (IEEE 1789 friendly).

Rise time < 200 ns to avoid ghosting.

RFQ line: “Provide IEEE 1789 metrics and phosphor decay chart.”

4 · Why “SMD” Changes Assembly & Heat Flow

Surface-mount means lower labor but tighter reflow; keep ramp at 3 °C/s and peak 245 °C to avoid solder voids.

SMD devices reflow directly, cutting manual insertion cost by 80 %. The 2835’s exposed pad drops heat straight to copper, unlike radial leads that float in epoxy. But you must control voids—> 30 % void area raises RθJA and kills lifetime. Use 0.13 mm stencil, type-4 paste, nitrogen reflow if possible.

SMT best practices:

Stencil area ratio ≥ 0.66 for reliable paste transfer.

No-clean flux to avoid water-soluble residue under lens.

X-ray sample first batch; reject if voids exceed IPC-7093 limit.

Include reflow SOP link.

5 · Brightness Showdown: 2835 vs 5050

Per package, 5050 shines brighter; per dollar per lumen on dense strips, bin-tight 2835 wins—unless you need RGB, where 5050 still rules.

Single-white 5050: 210–240 lm @ 150 mA; white 2835: 60–70 lm @ 65 mA. But strip math: eight 2835s (520 mA total) out-lumen three 5050s (450 mA) while spreading heat. Landed $/klm favors 2835 by ~8–12 % when you include driver and duty. RGB requires 5050’s tri-die architecture, so keep both SKUs in your library.

Decision matrix:

Retail shelves, task lights → 2835, Ra 80–90, ≤ 3 SDCM.

Stage lighting, digital pixels → 5050 RGB, IC-integrated if addressable.

Outdoor signage → 5050 white for punch, but derate current 20 % for heat.

Add strip cost calculator.

RFQ Bullets (Copy/Paste)

2835 White — ≥ 150 lm/W @ 65 mA (Ra 80) / ≥ 130 lm/W (Ra 90); RθJC ≤ 12 °C/W.

Dimming — IEEE 1789: Percent Flicker < 10 %, Flicker Index < 0.05 @ 100 %.

Binning — ≤ 3 SDCM (≤ 2 premium); shipment ≤ 2 adjoining bins; Δu′v′ ≤ 0.006 after 1 000 h @ 105 °C.

Reliability — HTOL 1 000 h 105 °C, 85/85 1 000 h, Thermal Shock –40↔125 °C, Surge 2 kV; lumen loss ≤ 10 %.

Pricing — Quote $/pc & $/klm landed (FOB & DDP NY); include NET-30/60 options and bin premiums.

Need a Bin Map or Flicker Test Plan?

Send your CCT, CRI, and dimming range. I’ll deliver a bin-reservation chart and lab flicker SOP tailored to your driver—so you can quote with confidence tomorrow.

Comments